Precise Creasing – Efficient Application

Tears at the fold or problems in the further processing of the packaging will be a thing of the past thanks to our high-quality creasing matrixes.

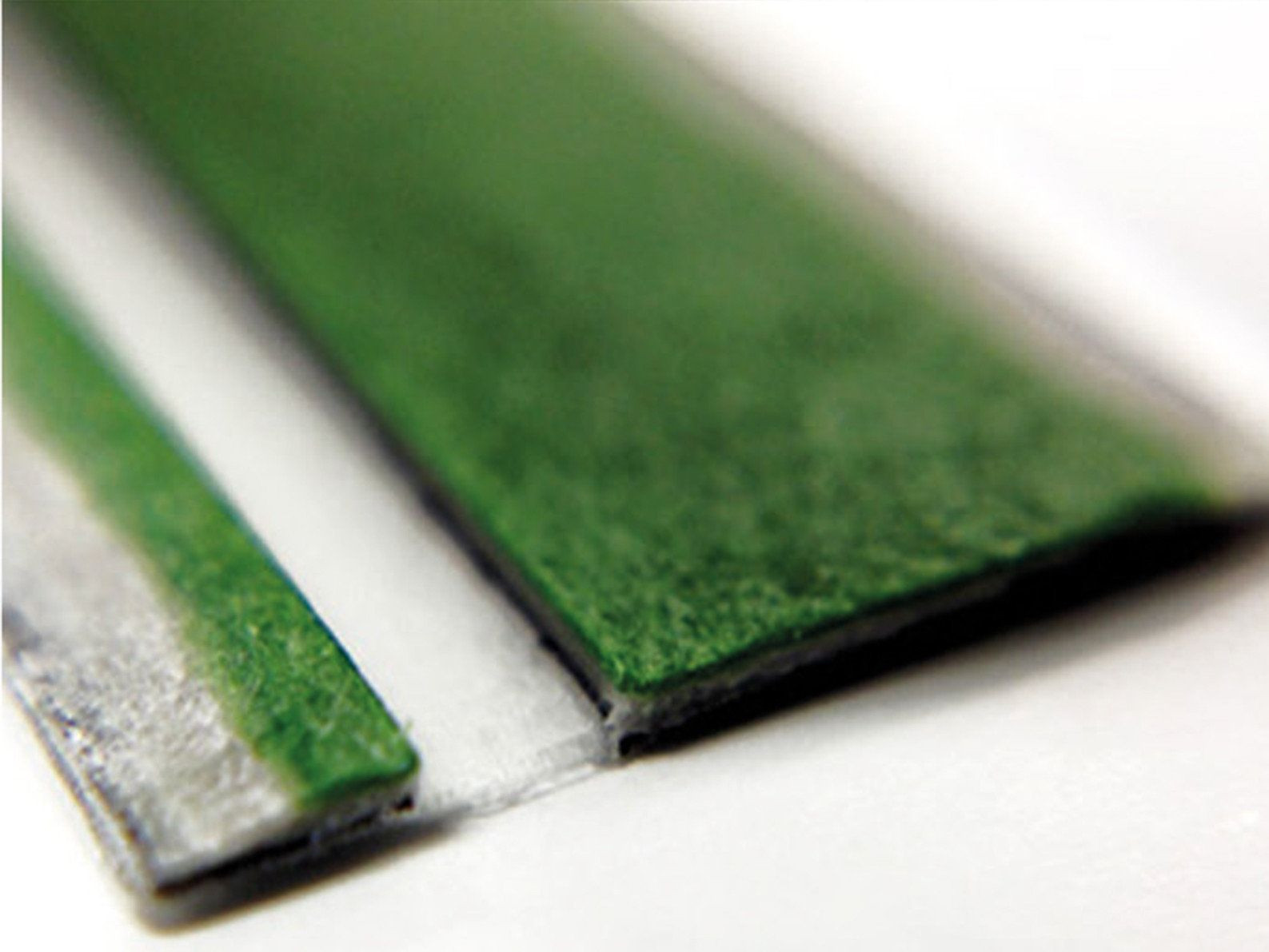

The basis of our creasing matrixes is made of vulcanised fibre and therefore has excellent mechanical properties. Its extreme hardness and toughness enable a wear-resistant mould contour. In addition, vulcanised fibre is an antistatic material that does not attract dust and therefore does not clog the creasing channel.

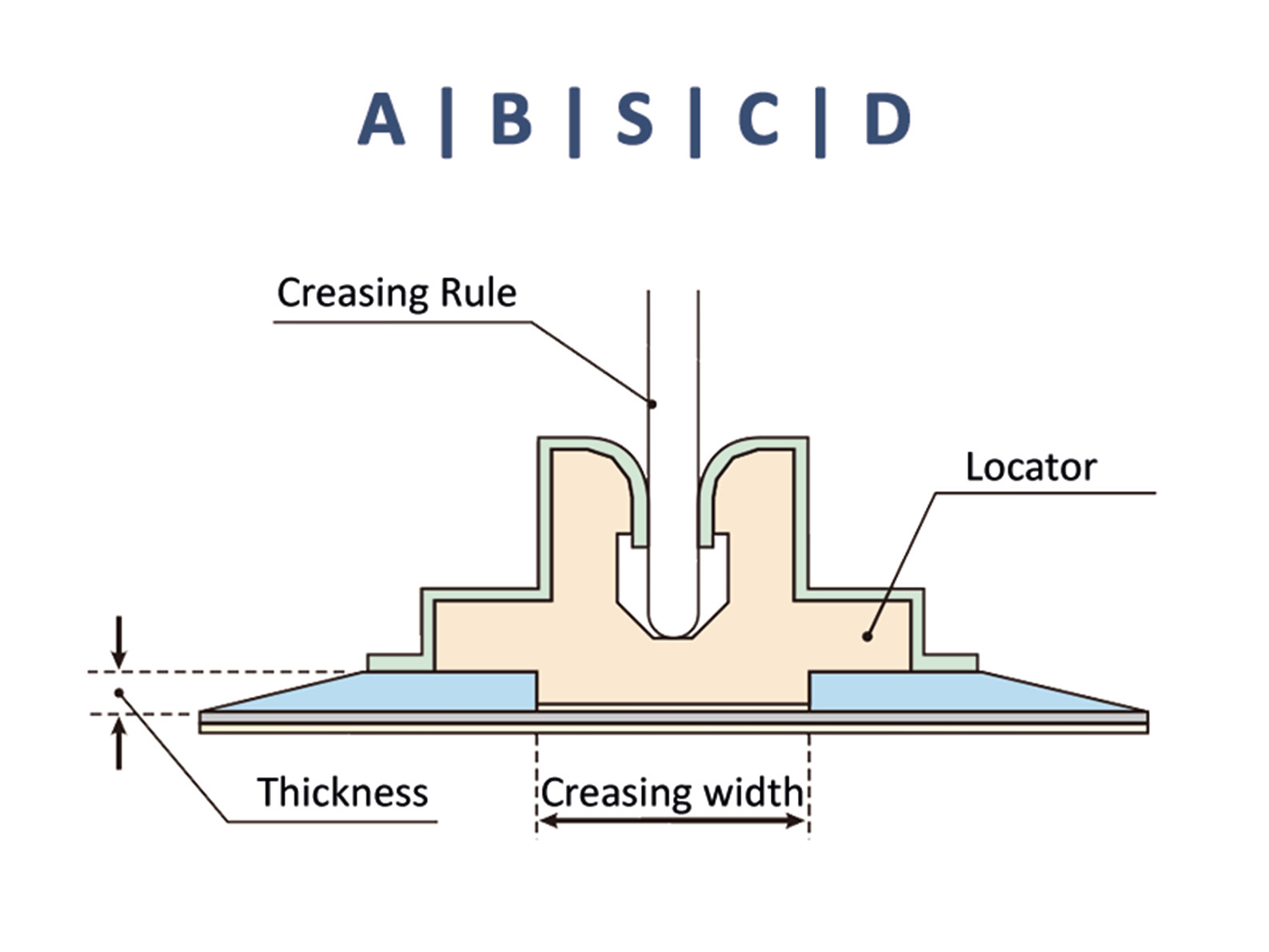

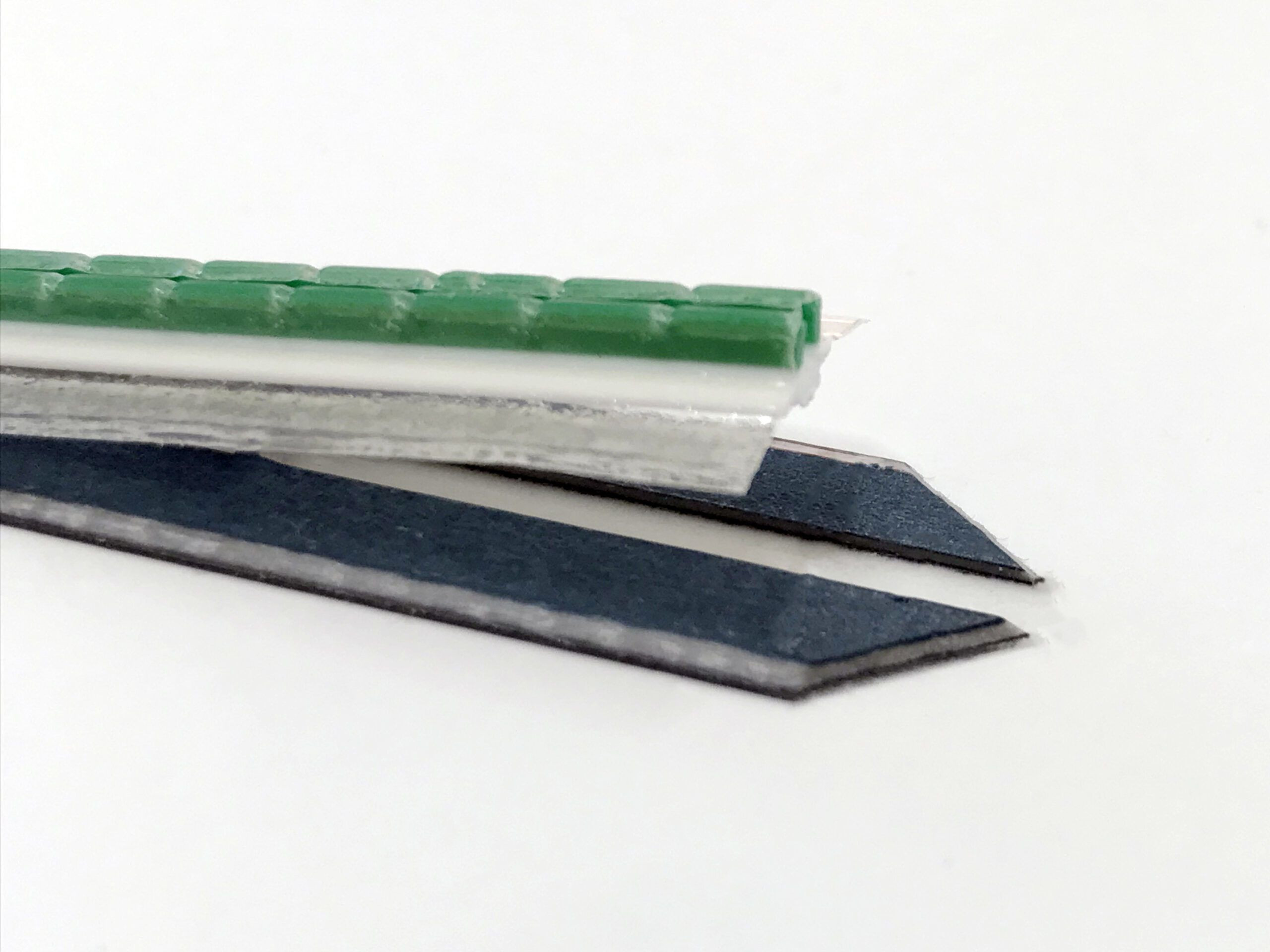

The locators are precisely designed for the corresponding creasing rule widths. This guarantees that the creasing rule is always positioned centrally to the creasing channel. In addition, the precisely fitting guide stripe profile prevents the tool from falling down when it is turned over. Furthermore, lateral notches have been added which serve as additional nicks and fix the creasing rules even better.

Advantages:

- Higher Creasing Quality

- Better Production Stability

- Lateral Film Gluing

- More Environmentally Friendly Materials