Daiso Europe

Laser cleaning of anilox and anilox rollers

Laser cleaning of anilox and anilox rollers

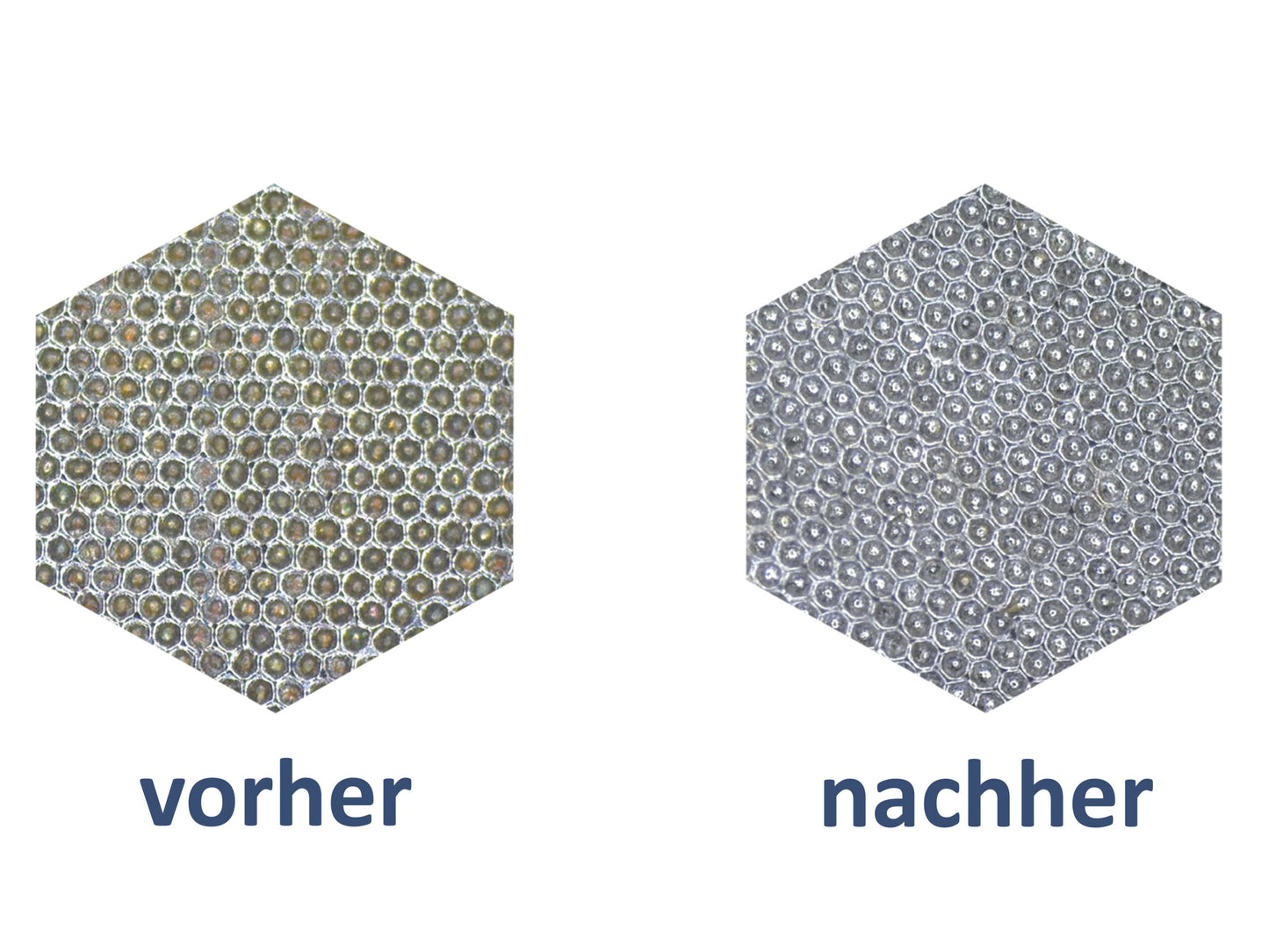

Laser cleaning removes all paint and varnish residues without damaging the microstructured surface. The laser beams penetrate the deepest cells of the roller surface and evaporate the dirt deposits, which consist of pigments and polymers.

Share

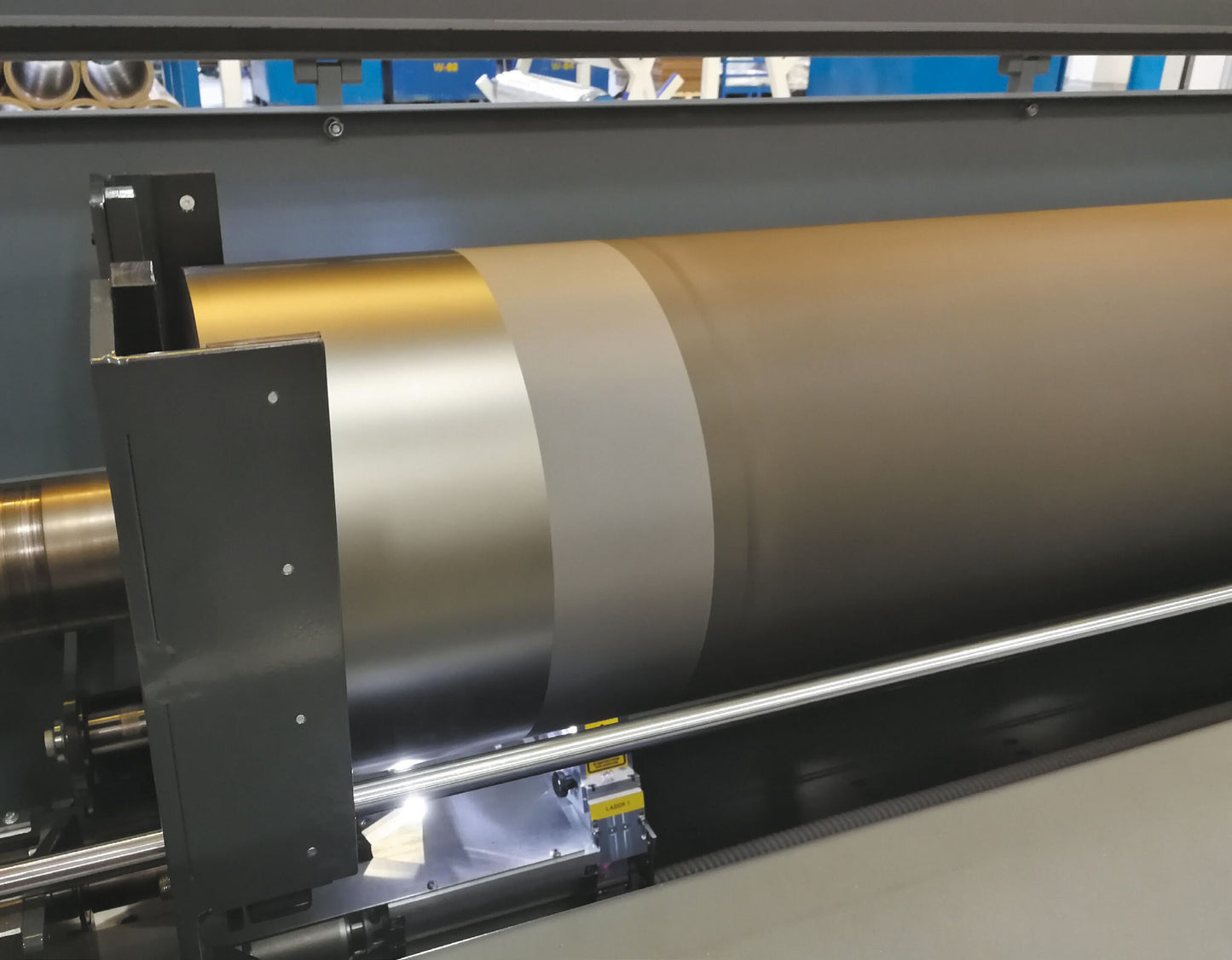

Laser cleaning at your location

The anilox roller transfers a predefined volume of inks, varnishes, adhesives, or other coating media to the printing form in a consistent and repeatable manner. However, it is inevitable that ink residues remain in the cells, which build up over time and lead to performance losses in ink transfer and thus the achievable product quality. Thus, the anilox roller has a decisive influence on the achievable quality level.

To counteract this process, your anilox rollers should be laser cleaned at least twice a year, as conventional cleaning methods only partially remove the residues.

Advantages

- More thorough and effective than conventional methods

- Consistently high print quality

- Effective restoration of cell volume and surface tension

- Inline and offline cleaning

- No consumables such as water, chemicals or granules

- Environmentally friendly

- 30 minutes cleaning time for 100 cm length